"Chocolate is wonderful: mild, sensual, deep, dark, sumptuous, satisfying, potent, massive, creamy, seductive, stimulating, gorgeous, excessive, silky, smooth, luxurious, celestial. Chocolate is ruin, happiness, pleasure, ecstasy, imagination ... it allows us to sin, makes us healthy, happy and elegant." (Elaine Sherman) |

|

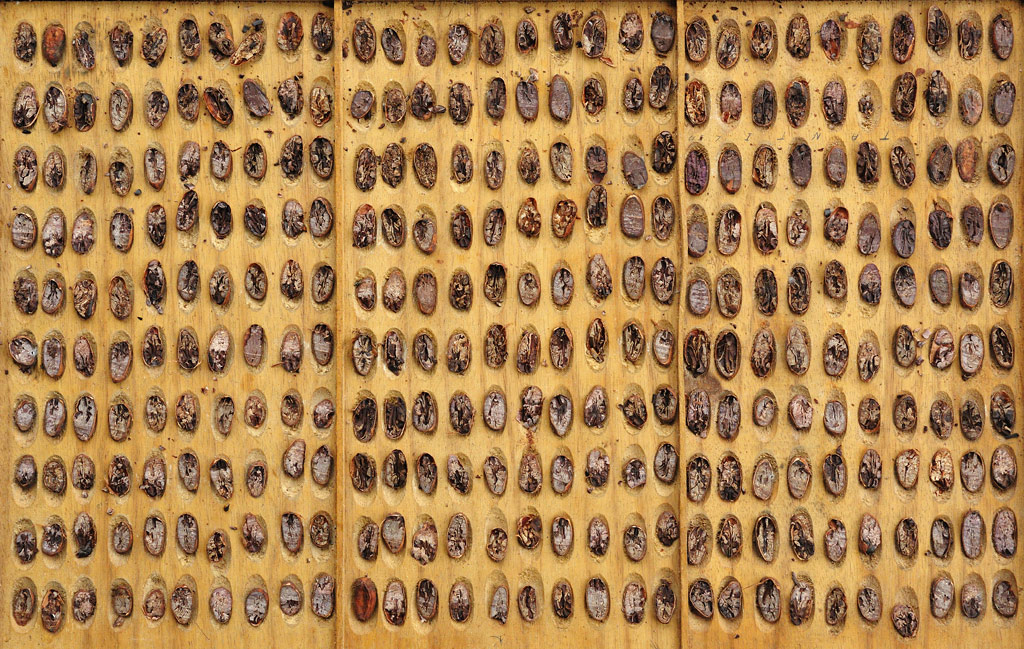

CLASSIFICATION: (A sample

cutting)

(Classificação: 'A prova de corte') Wherever cocoa is sold, it must also be evaluated. This is done by means of classification.

Analysis is done with reference to sample cuttings, moisture-content

and taste. For the sample cuttting a classifier cuts 300 cocoa beans

lengthwise and places the halves

into the hollows of the classification board. With the help of this

method the classifier can detect defects such as mould growth,

insect damage, sprouted or flattened beans and he can divide the beans into corresponding grades.

Classification of cocoa beans |

|

PEOPLE OF THE FARM, II

('Pessoas da fazenda, II')  Carlos Roberto, foreman  One of the 'tropeiros' of the farm  Outdoor bodycare  Dona Elaine, housekeeper  Gymnastics hour ('aula de ginástica') in the farm school  Role reversal: geography lesson with the 'German' ('o alemão') The

teacher took advantage of the (geography) lesson and let me do a

little unit: Germany, Europe, flying by plane, does

cocoa

grow in Europe? Why not? And coffee? Why not? etc. I'm not sure how

much the kids understood but I'm sure they were impressed - as I was.

Then the teacher took my camera

and photographed our little "lesson". Then the teacher took my camera

and photographed our little "lesson".  A farm worker's daughter |