|

THE DRYING AREAS

('As barcaças') The

roofs of the workers' houses serve as drying areas

“barcaças” for the cocoa beans. The corrugated iron

rooftop is mounted on rails and is therefore retractable, allowing the

wooden floor underneath to be used as a drying area. At night and when

it rains, the “barcaceiros” close the roofs.

House with retractable roof. During the rainy season the windows are often protected with plastic or canvas sheets. Dogs bask in the heat of the sun after the rain.  Manuel cleans the dried cocoa  Railed roof construction behind the houses  View of the back of the house with railed construction  Drying-roof without house attached |

|

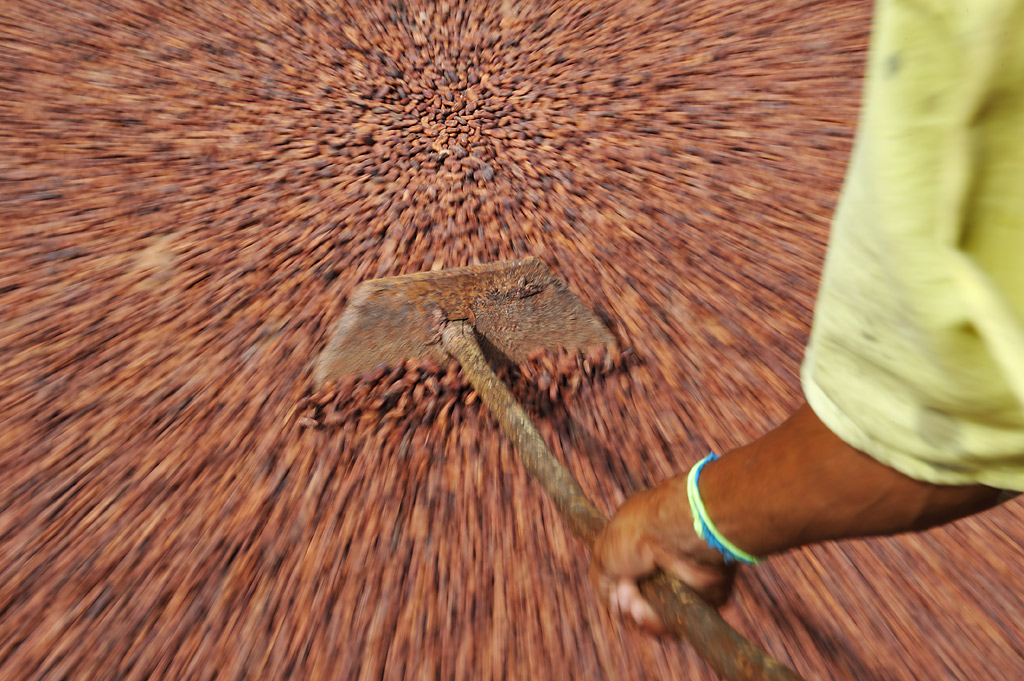

DRYING COCOA

('Secar cacau') After

fermentation the cocoa beans still contain about 60% water. The

barcaceiros let the beans dry in the sun for about a week. In the rainy

season they use a hot-air oven.

Since the cocoa beans are still soft and slippery right after fermentation, Manuel turns the beans at the beginning of the process, shuffling with his feet through the slippery ground. Manuel spends the whole day turning over the beans in this way. During the drying process the weight of the beans is reduced by more than half and their water content drops to about 5 to 7%.  Drying cocoa ('secar cacau')  Drying cocoa If

everything is done well - from selecting the right fruit (variety,

maturity) to drying without mold growth - the result will be, as here,

a high quality cocoa

('cacau fino') - the cocoa variety alone is not

sufficient, even if advertising would have us believe it.

Drying cocoa  Turning cocoa  Turning cocoa  Turning cocoa „Cocoa flavour. Dancing the beat of the drum, exuding his wasteful aroma.” (Aztec poet) TREADING ON THE BEANS ('Pisar cacau')  Narcísio ('barcaceiro') Narcísio - and this

is no nickname - is another barcaçeiro.

Before the beans are quite dry, Narcisio treads, barefoot, on the

bean-piles with rhythmic movements. Previously, he pushes them into a

small pile and moistens

them slightly with water. Then he begins to tread rhythmically, moving

in circles over the lower beans first and gradually reducing the

pile. He does this for hours. It looks like a dance without

music.

The friction and pressure of his “dance” cleanses the beans of any remaining fruit pulp and prevents the formation of mould which would otherwise form very quickly in the prevailing heat and humidity.  The beans are formed into smaller piles

"Dancing on the beans" "... spread over the drying-roofs, the cocoa was drying in the sun. We were also dancing and singing there. Our feet were already flat and our toes spread out. After eight days, the cocoa beans were black and they smelled of chocolate." (from: Jorge Amado, Cocoa) |

|

THE COCOA BEAN

('A amêndoa de cacau') During

the drying process, the beans take on their brown to dark brown color

and their delicious, chocolaty aroma is formed. At the same time they

lose part of their bitter taste. Each bean is made up - among other

ingredients - of fat (over 50%!), starch (7%), proteins (12%),

theobromine and

caffeine.

Drying cocoa beans  Longitudinal cross-section of a cocoa bean. The high proportion of fat can clearly be seen.  Cocoa Beans: a poster (poster "Amêndoas de Cacau")  Cocoa depot ('armazém do cacau'). The cocoa beans are stored in jute or plastic sacks |