_____________________________________________________________________________________________________________________________

[Home]

Gifts of the Gods

Diamonds and India – a Photo Documentary

- Page 3 -

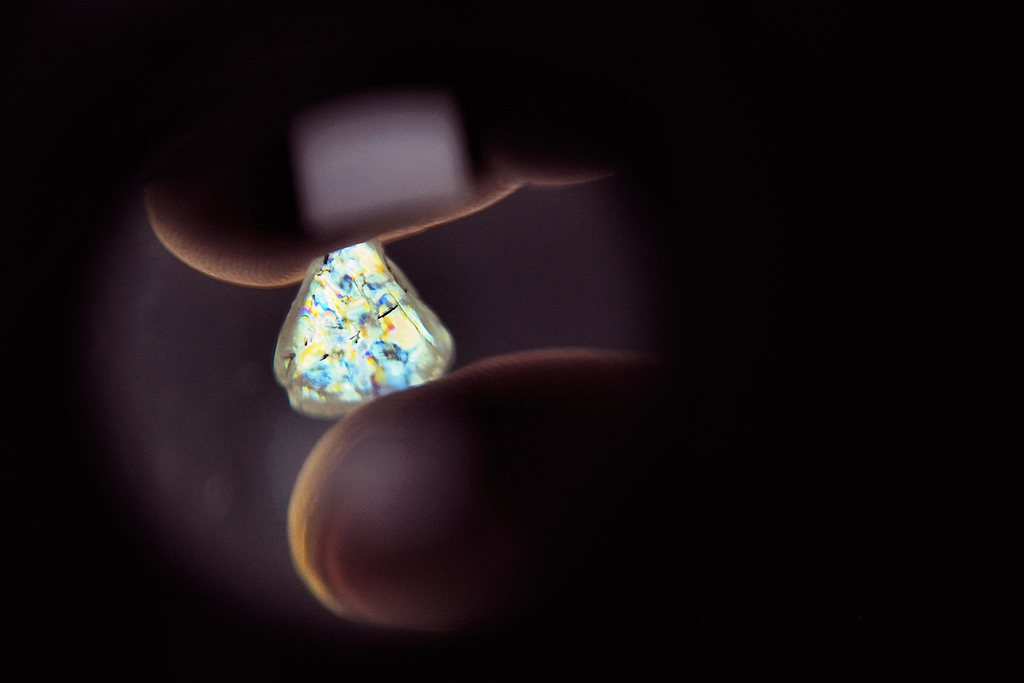

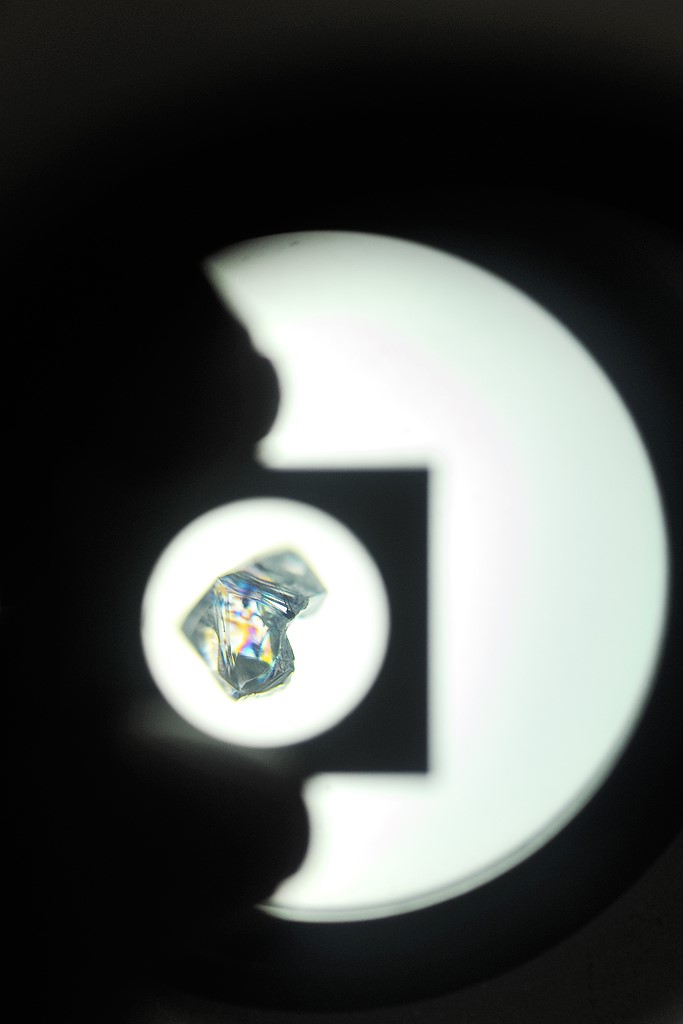

Diamond under a Polariscope

| Diamonds can be split in several angles. This cleavage is dependent on the structure of the crystal lattice. While cutting a precious stone, one must consider the cleavage, because even a little excess pressure on a wrong point can crack a diamond. Even exposure to excessive heat, for e.g. with laser, can create greater inner tension on certain points leading to the stone breaking. With a polariscope one can see the optical properties, the “multi-colours” of a diamond (“pleochroism”). The reason for this effect is the uneven absorption of light depending on the direction of its dispersion. If one observes a diamond through a polariscope, one can see the tension over the different reflecting colours! It allows for the assessment of the correct starting point with the lasers. For if one cuts the diamond at the point of highest stress, there is a danger that it will shatter. |

The Polariscope |

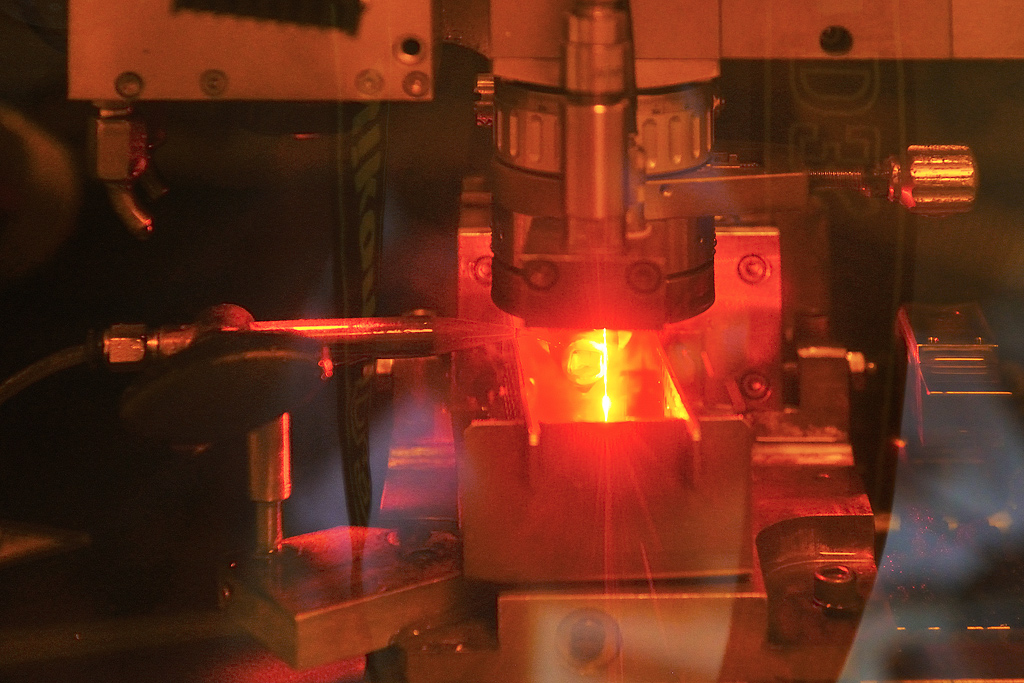

Preparation for the laser |

Most advanced, very potent laser – I could only photograph it through a closed door

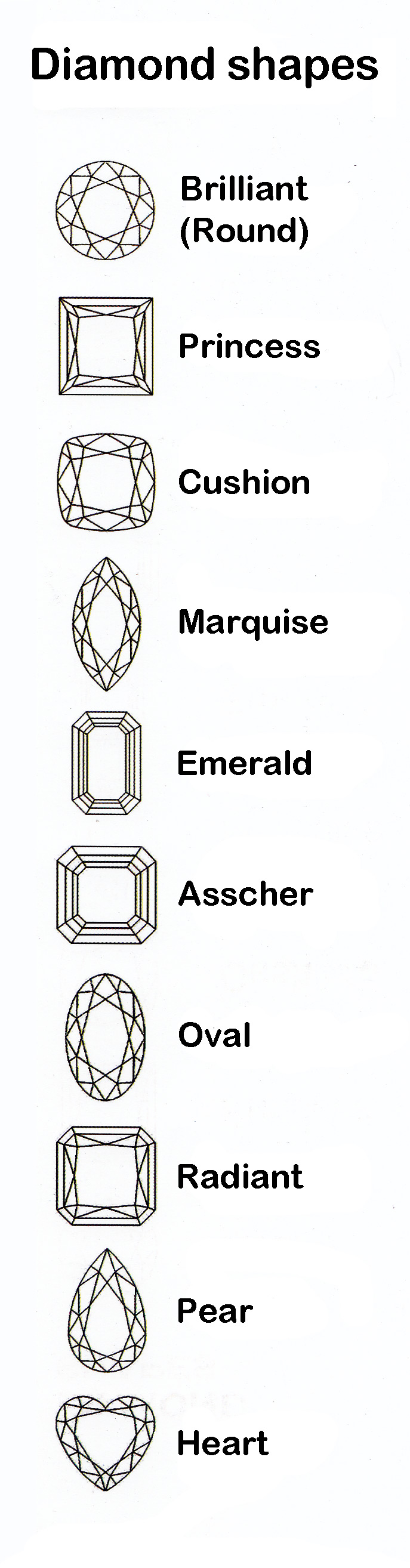

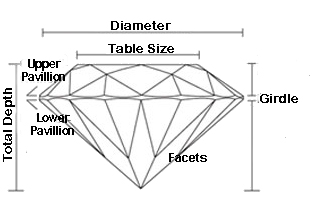

Important terms of a diamond

| What really constitutes a cut

diamond and how can one discern its quality? In July 2010, new rules

for the grading of diamonds came into force. They were officially

termed as the “5Cs”, whereby the "5th C" stands for

“Character”. The entity authorizing the

grading rules is the “International Diamond Council”

in Antwerp. The “5Cs” (+1) are as follows: 1. Carat (weight) 2. Clarity (purity) 3. Colour 4. Cut 5. Character --- 6. Confidence = trust (in the seller) [Explanation of the "5Cs"... Open here] |

[Everything about Diamond shapes… Open here] |

[More about diamond prices…] |

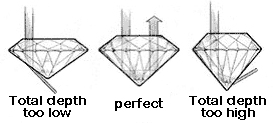

Reflection of light and proportion

of a diamond

One of the many cutting rooms  Diamond cutters |

A cut diamond has the highest

existing refraction of light (with a coefficient of 2.42!) and a

powerful brilliance

paired with a remarkable dispersion, which is why it is traditionally

ground and polished as a gemstone. The brilliance of a diamond is

brought about by the total amount of white light that is reflected

within the diamond. The so-called fire in a diamond, on the other hand, results from the perception of colour in the eye of the beholder when the white light while viewing disperses into its prismatic colours, caused by the cut facets of the diamond. The diamond cutter also has the task of ensuring an optimal balance between the two properties, brilliance and fire, in a diamond. For this reason, a diamond cutter requires not only talent, but also immense experience in the job. Perfectly cut diamonds enhance the price of a diamond, irrespective of its other attributes. Thus, the diamond cutter has an important, economic responsibility for the company. A good diamond cutter balances thus the facets in size and symmetry as well as the alignment of the angles and proportions optimally. As only when all the details add up – here, especially the ratio of the upper part to the lower part, as well as the table size in relation to the height of the upper part - is the total reflection of the light possible. As the light escapes from the table, it disperses in its prismatic colours. This occurrence, (“dispersion”), allows the fire as well as the brilliance of the diamond to be fully displayed. If the diamonds are cut too narrow or too flat, the light will not be reflected and the brilliance and the fire will be lost. |

Facet cut The grinding wheels are metal discs, to which the abrasive diamond powder is applied as a thin layer in a galvanized nickel matrix. While grinding, the facets of the diamonds are laid out in precise angles. Therefore, there are varying brackets, which are attached as per the type of facet and then held at a specific angle at the grinding wheel. The girdle of the diamond is its widest part. According to its size, all other dimensions are given in percentages. The girdle should lie in one plane, not too thick, nor uneven. The optimal girdle strength is “fine middle” (mid-range thickness). In order to achieve the best possible appearance, the girdle has to be worked on in a specific step. It should be consistent and uniform, and have no major differences in strength. The strength of the girdle is determined by the cut, but through precise grinding with a special machine, the best possible rounding and form can be achieved. [Classification of the cutting grade of the girdle… Open here]  The precise

cut of the girdle is a specific work step

|

|

| Once

the diamond is fully cut, only then are the facets polished at the end.

If this polishing is not carried out according to the rules, scratches

and lines can be left behind. An excellently polished diamond will have

practically no scratches. While buying a diamond, it is recommended

that a diamond with at least a polish grade of

“good” be selected. Before a diamond is sent for

sale, all relevant parameters of quality are once again examined under

the microscope. If improvable defects are discovered then the stone is

sent back to the according department. Only at the end is the diamond polished |

|

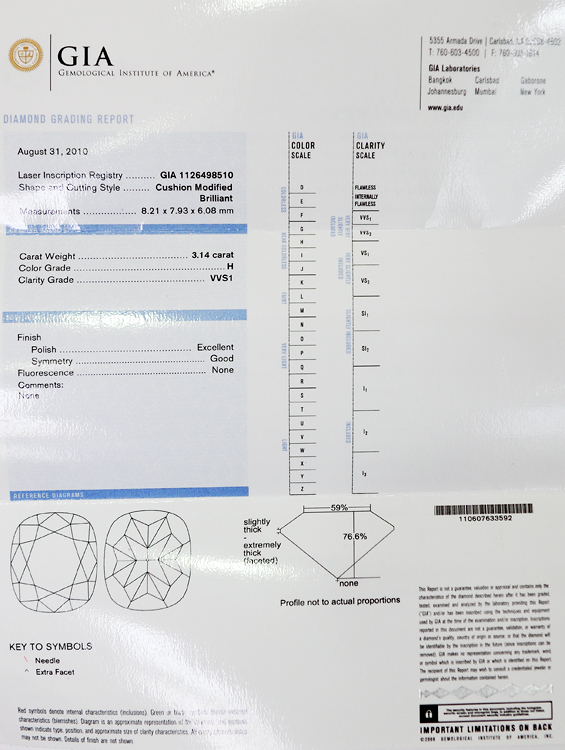

| The

diamonds cut here are sent to the wholesalers, retailers and jewelers

for sale, some of them in India and also in the USA. Important for sale

is the Certificate from the Gemological Institute of America (GIA). All

diamonds that are above 1 carat are sent to the laboratories in New

York for certification. They are examined and then they receive the

GIA-Laser-Code for diamonds, which is engraved on the girdle. This Code

is transferred on to the Certificate, which is uniquely assigned to it,

ensuring the stone is always clearly identifiable. Sanjay Bhalla explains, “A diamond with the GIA-Lasercode is in this way provided with protection, which creates further confidence among the clients. ‘De Beers ‘Forevermark’ follows this same goal. One should never buy a (big) diamond without the internationally recognized certificate. It is necessary to be cautious even with the term “enhanced” in the certificate. Such diamonds are artificially improved and are of lesser value. All diamonds certified from the important, internationally recognized institutes are furnished with a special expertise number on the girdle, inscribed by laser, just like for example at the GIA. [Important certificates… Open here] |

|

Final Inspection, under the microscope and on the weighing balance |

|

GIA-Certificate  GIA Code for the girdle (click to enlarge) |

“Confidence is good,

but Inspection better” applies to companies that work with

diamonds quite aptly. My friendly companion, Mr. Gaurav Duggal, from

Hari Krishna Exports explained to me how his company solved this

inspection problem: Every diamond that a worker is issued for

processing is registered. If the worker leaves his work place, he must again surrender the diamond/s, whereby they are registered once more, so they always know of the whereabouts of the diamonds. I think this is a good solution because the company saves on the costly and cumbersome search for specific persons, which due to sheer volume would take too long. The average wage of the worker in a diamond firm depends naturally on his skill, and also on the size of the diamonds, which they are processing. A diamond cutter, who cuts a diamond under 3 carats earns a monthly average wage in the range of INR 18,000 to 20,000 (5/2015 = 250 to 280 €). Naturally, one must consider these numbers in relation to the other wages and general living expenses in Surat, which then make it a good average monthly wage. The rents are especially low, for example, as compared to in Mumbai, from where, in the last few years, a large part of the diamond business has moved to Surat. Furthermore, in the firms, at least those visited by me, there are good social benefits and generous bonuses. The people live partly in company houses, they eat lunch free of cost in the company canteens, in the afternoon there is free “chai” (tea), there is a company temple, an attached garden for the afternoon break, and at Hari Krishna Exports, I saw a massage sofa, just like the ones you find at airports. The company owns its own school for the diamond cutters, where young workers are introduced to the responsibility of this work. |

| The biggest bonuses in the whole of India were given by Hari Krishna Exports in the year 2014 at Diwali, the Indian festival of lights, an important Hindu festival lasting for many days, which perhaps one, due to its spiritual and social reference can compare to the Christian festival, Christmas. 1,200 employees of the company who had qualified for the company “Loyalty Programme” could as bonus, choose between three gifts: a Fiat Punto, a deposit payment for a 2-bedroom apartment, or gold and diamond jewellery. | |

[Quotes, Thanks and Concerned Persons… Open here] |

|

End

|

|

© Copyright: Photos and Text: Jochen Weber

[TOP]