page 3

The Production of Cigars

| Since 1873, when Gerhard (Geraldo) opened his cigar factory in São Félix, cigars were produced manually in the region and also in this building, among others. The cigar rollers are called torcedores (m) or torcedoras (f) in international literature of cigars. In Brazil, where this profession is primarily practiced by women, the expression charuteiras, which originates from charuto [pron: sharuto], Portuguese for cigar, is also used. A proficient charuteira can, on a given day, produce up to 200 top-cigars. |

"A cigar can be sometimes just a cigar."

(Siegmund Freud)

Cris, charuteira

Saint Antonio of Padua

"No, but we can remain good friends."

(Groucho Marx, on his wife’s demands to stop smoking cigars)

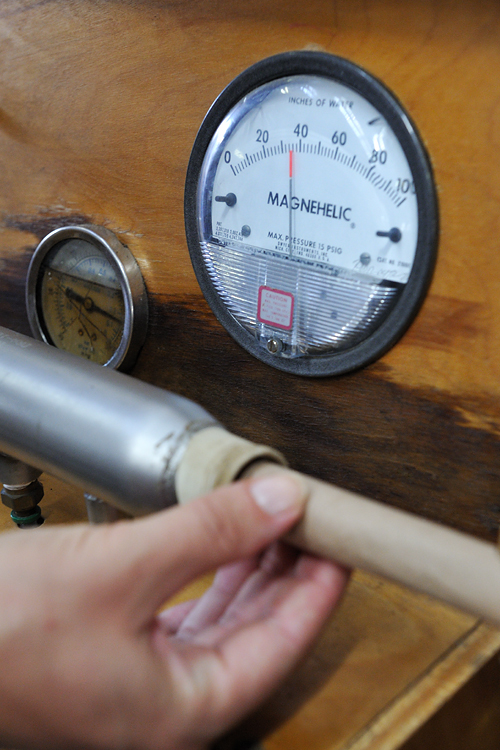

| Cigar bands and Packaging Now only the cigar band (‘sleeve’) has to be attached, and for that a scale is used, which ensures that it is always attached at the same height. The finished cigars are now stored in an air-conditioned room for at least four weeks, so that the extra moisture that had got attached to them during processing, is released. During this time the taste develops further and the tobacco blend combines to create a unified, rounded flavour. Before the cigars are finally packed in the wooden boxes that are specially made in-house, there is one last quality control that follows: the weight and the moisture are once again measured. A skilled colour sorter chooses the cigars according to colours and places, as far as possible, the same colour cigars together in every package. He sorts the possible variations in colour shades, which turn darker starting from left to right. Each crate has its own checking number. |

|

|

|

|

|

|

|

|

|

„I have made it my rule, to smoke no more than one cigar simultaneously.“

(Mark Twain)

"Tobacco hands"

© Copyright: Photos and text: Jochen Weber

[TOP]