A photo documentary on coffee cultivation in Brazil

- Page 3 -

|

|

The Transport ('O transporte') Before the workers load the coffee cherries into the trailer of the tractor, the foreman registers the coffee sacks, so that later the wages can be paid to the people according to the work done by them. Once all the sacks have been emptied, the ride leaves for the water canal. After the mechanical harvest, the trailer is directly filled by the harvest machine, and naturally nothing needs to be registered for that. As the tractor comes to the water canal, Paulo takes over the load; retracting backwards is “a top priority”, since the trailer had tipped over here once. Then one of the workers unloads the coffee cherries, the flowing water takes the cherries with it in the canal; the force of the outflow must be regulated, so that the water pressure is not too high. A barrier in the water canal holds back the cherries that have sunk i.e. the heavier (ripe and unripe), the lighter (over ripe, dry) and consequently, the ones floating on top that are flowing away with the water. |

The facility

The coffee offloaded for ‘washing’

|

The Processing –

The Washing

('O processamento – a lavagem’) In the water canal the ripe red and the unripe green, that is the moist and thus the heavy cherries are separated from the dry ones floating on top. The workers lay out both the cherry groups to dry separately after this procedure. To this Paulo explains: “They need varying time periods to dry because of their unequal levels of maturity. If they stay together, the ‘passas’ and 'bóias' or the over ripe cherries would later dry up under the sun.” Controlling the water supply and the speed of the outflow of the coffee cherries is likewise a priority: “Because a lot can go wrong, especially due to the quantity of water. With too much water coming in, the whole coffee shoots back into the field. This has happened before and that is why I prefer to do it myself,” says Paulo. At the end of the canal is the area for placing the cherries for drying in the air and under the sun and behind that is the warehouse, the so-called ‘tulha’. |

|

The water whirls the coffee in the canal

In the water canal

End of work

Drying area for coffee – in the background is the coffee warehouse, the 'tulha'

Modified motorcycle for turning coffee

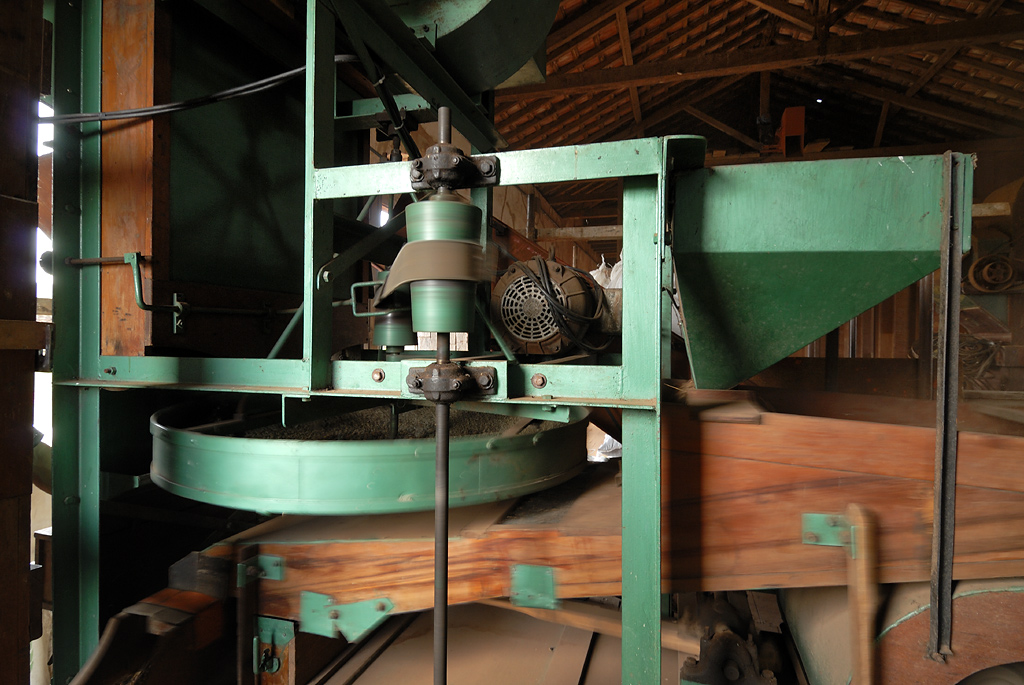

Husking machine of the Fazenda Boa Vista

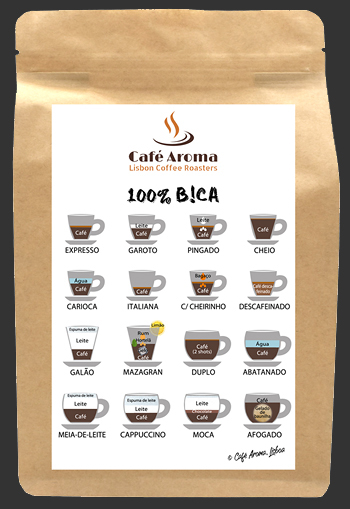

Advertisement

A typical good Portuguese espresso for all its variants.

The basis of all known espresso drinks!

(An espresso is called a "bica" in southern Portugal, especially in Lisbon)

Both the classic blend with a moderate Robusta coffee content and medium-dark roasting

produce a good typical Portuguese espresso for all its variants: Let our label inspire you!

© Copyright Photographs and Texts: Jochen Weber